Types of Lithium Battery Cells: Pouch, Prismatic, Cylindrical

Introduction

Lithium-ion batteries come in several different cell formats, each designed to balance safety, performance, energy density, and form factor. Among the most widely used structures today are pouch cells, prismatic cells, and cylindrical cells. These three cell types power everything from electric vehicles and energy-storage systems to consumer electronics, EV scooters, and industrial equipment.

Choosing the right cell format matters because it influences thermal performance, battery pack design, cycle life, manufacturing complexity, and cost. For example, the automotive industry often favors prismatic and pouch cells for their flexible shapes, while power tools continue to rely heavily on cylindrical cells due to their robustness. Energy-storage manufacturers may choose prismatic cells for stability, while consumer electronics typically adopt pouch cells for their slim profile.

This guide breaks down the structure, advantages, disadvantages, and typical application scenarios for each lithium cell type—helping engineers, buyers, and product developers select the most suitable solution for their energy requirements.

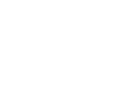

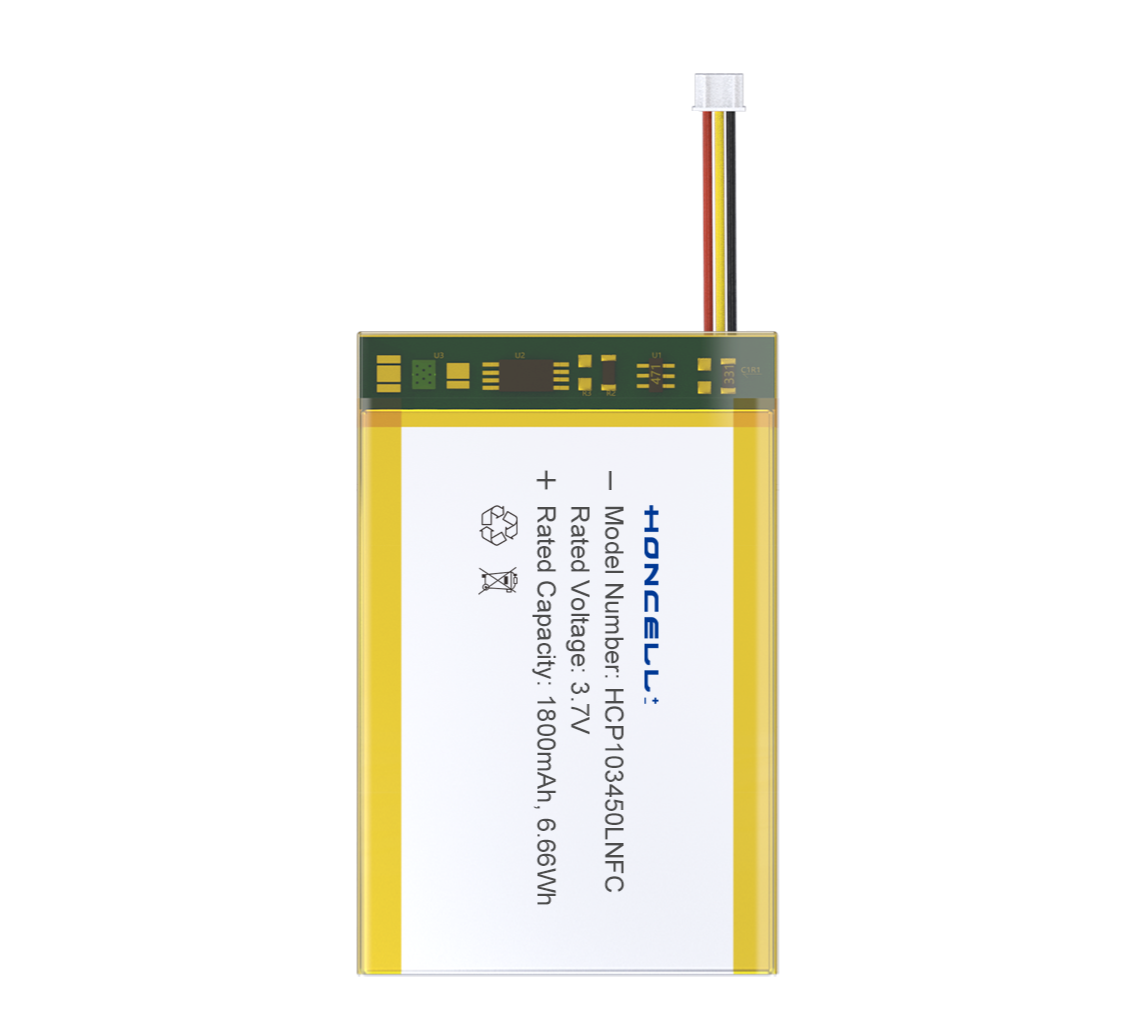

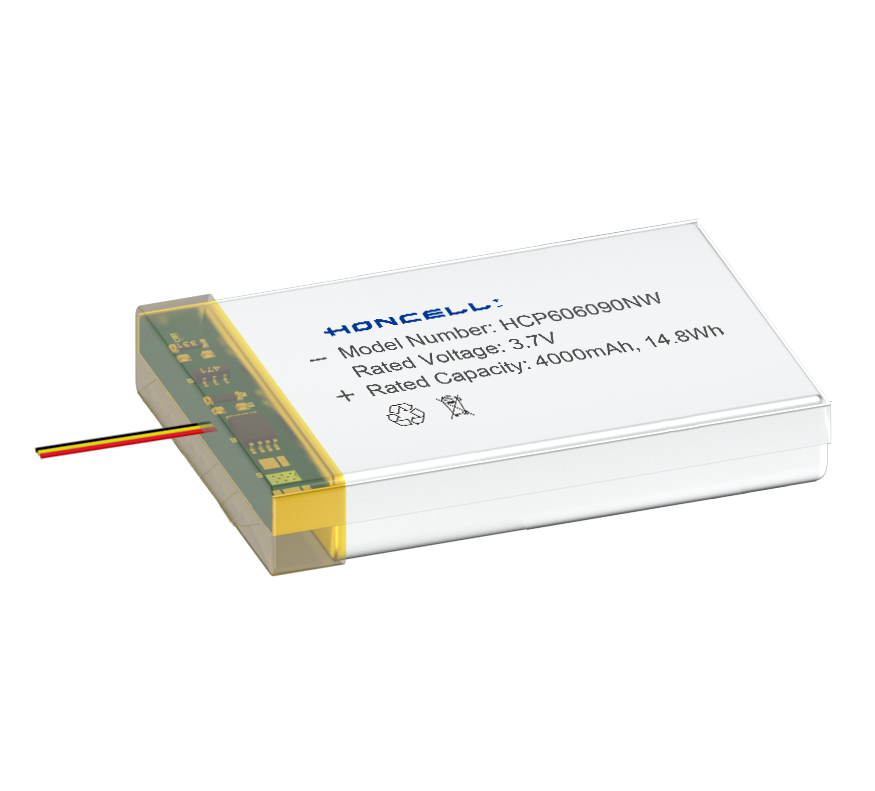

Pouch Cells

Pouch cells use a soft aluminum-laminated packaging material instead of a rigid metal casing. This construction gives them exceptional design flexibility, making them ideal for thin or irregularly shaped battery packs.

Characteristics of Pouch Cells

Pouch cells are popular in smartphones, tablets, drones, e-bikes, and increasingly in electric vehicles. Their unique design offers several distinctive characteristics:

1. High Energy Density

Because pouch cells eliminate the metal casing found in cylindrical and prismatic cells, they achieve more energy storage per unit weight and volume. This is why pouch cells dominate compact electronics where space efficiency is critical.

2. Lightweight and Flexible Form Factor

The soft packaging allows manufacturers to customize size, thickness, and shape. This flexibility is a key advantage for modern electronics, medical devices, and compact EV battery modules.

3. Lower Internal Resistance

The wide electrode layers inside pouch cells allow large surface area contact with the electrolyte. This reduces internal resistance, supporting:Higher discharge ratesBetter thermal managementImproved fast-charging capabilities

4. Requires Strict Structural Support

Because pouch cells lack rigid casing, they must be supported within the battery pack to prevent swelling and deformation during charging cycles.

5. Potential for Swelling

Gas buildup or electrolyte decomposition can cause pouch cells to expand. For this reason, thermal management and high-quality manufacturing are essential.

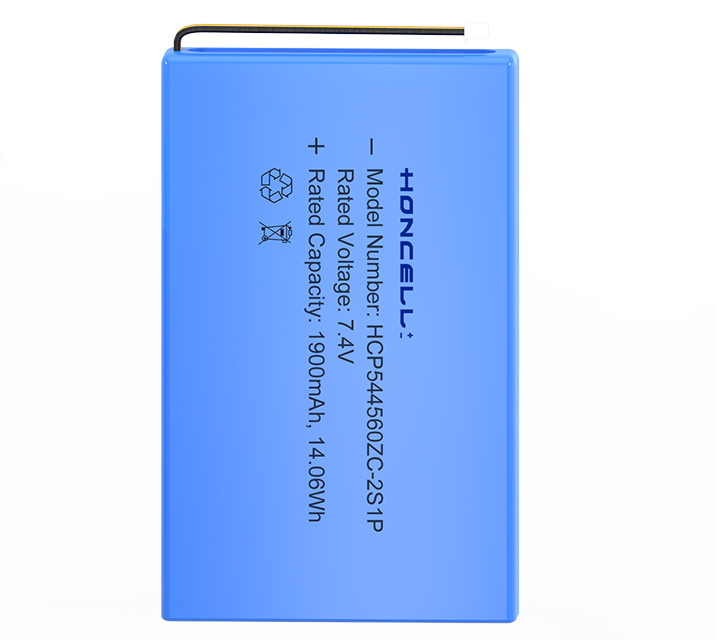

Prismatic Cells

Prismatic cells are rectangular, enclosed in a rigid aluminum or steel casing. Their structured format makes them particularly popular in energy-storage systems and electric vehicles.

Advantages

High packing efficiency within battery modules

Good structural strength

Lower risk of mechanical deformation

Reliable thermal performance

Disadvantages

Slightly lower energy density than pouch cells

More expensive to manufacture

Potential swelling over long-term use

Typical Applications

EV battery packs

Residential energy storage systems

Commercial ESS

UPS and telecom backup batteries

Prismatic cells are often chosen when stability and pack-level energy density are more important than individual cell energy density.

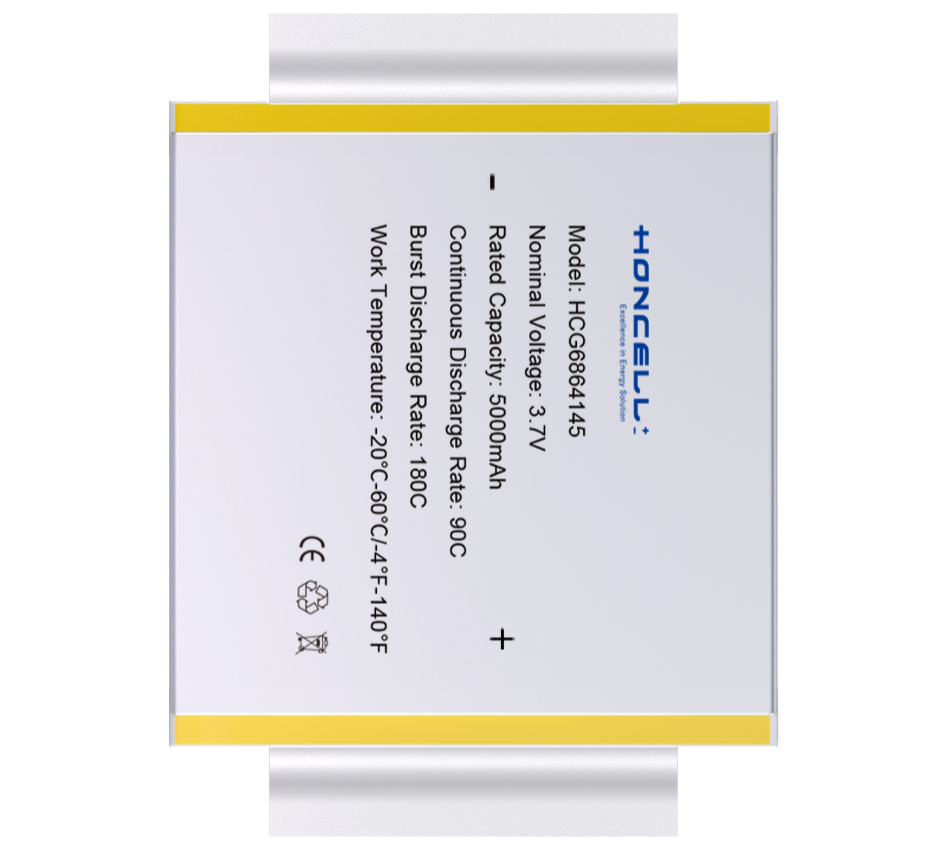

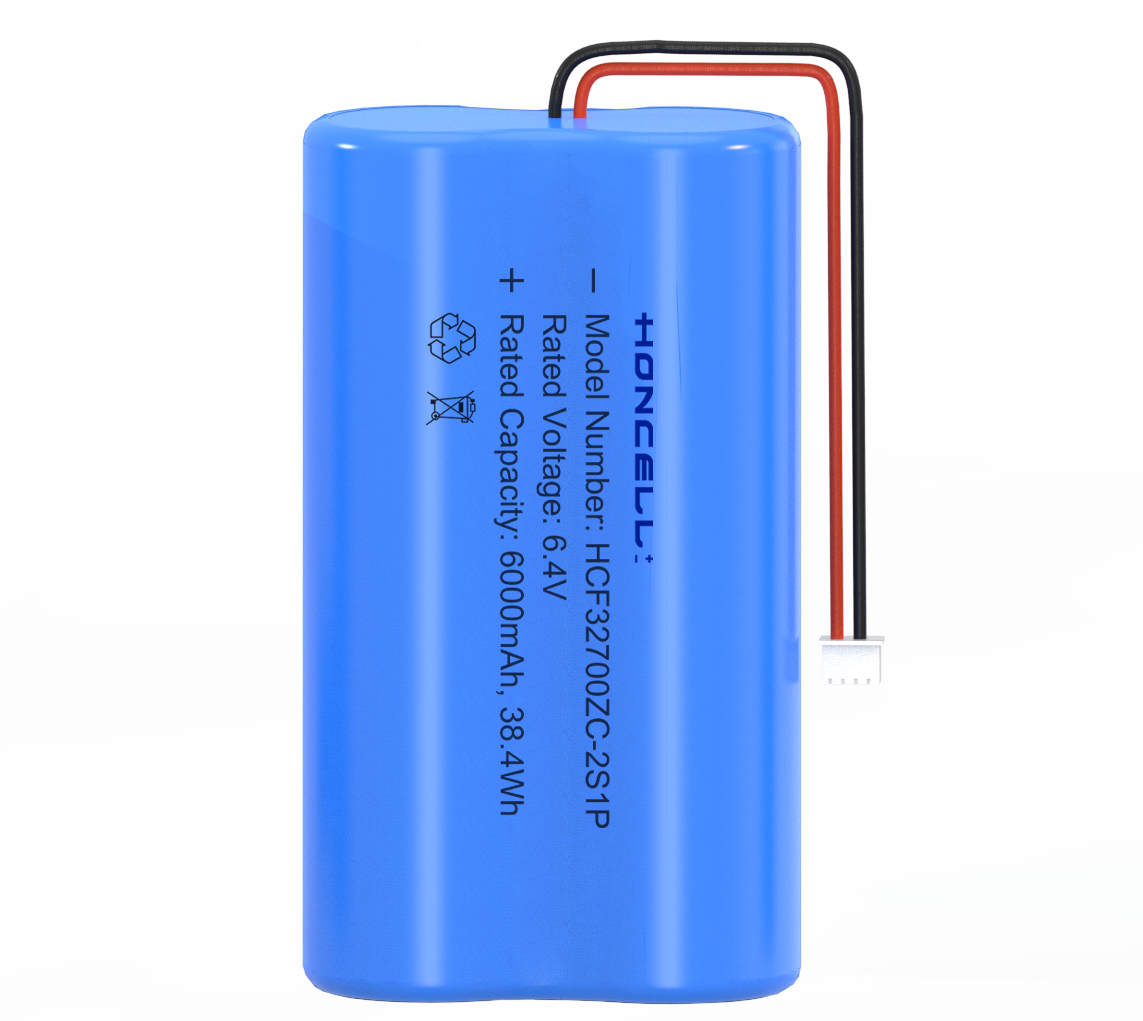

Cylindrical Cells

Cylindrical cells, such as the well-known 18650 and 21700 formats, are one of the oldest and most mature lithium cell types.

Advantages

Excellent mechanical stability

Strong tolerance to vibration and abuse

Efficient heat dissipation

Low manufacturing cost due to automation

Disadvantages

Lower volumetric energy density due to cylindrical shape

Less flexibility in pack design

Requires more space for arrays and cooling

Typical Applications

E-bikes and scooters

Electric vehicles (e.g., Tesla with 18650/21700)

Industrial applications

Outdoor power equipment

Cylindrical cells remain a market favorite because of their reliability, long cycle life, and cost efficiency.

FAQs

1. Which lithium battery cell type has the highest energy density?

Pouch cells generally offer the highest gravimetric and volumetric energy density because they do not require a rigid outer casing.

2. Are pouch cells safe for electric vehicles?

Yes. Many EV manufacturers use pouch cells, though they require robust structural support and thermal management due to their flexible casing.

3. Why do energy-storage systems prefer prismatic cells?

Their rectangular shape improves packing density, thermal stability, and maintenance efficiency in large battery modules.

4. Are cylindrical cells still relevant for EVs?

Absolutely. Tesla and other manufacturers continue to use cylindrical formats like 21700 due to their long cycle life and automated production.

5. Do pouch cells swell over time?

They can if subjected to high temperatures, poor charging conditions, or low-quality manufacturing. High-grade pouch cells maintain stability with proper BMS control.

6. Which cell type is best for high-power discharge applications?

Cylindrical cells are often preferred because they can handle higher discharge currents without thermal stress.

7. What are common sizes for cylindrical lithium cells?

18650, 21700, and 4680 are the most widely used in consumer and EV applications.

8. Are prismatic cells heavier than other types?

Yes, the metal casing increases weight, but it also enhances durability and structural integrity.

9. Which cell format is easiest to cool?

Cylindrical cells dissipate heat efficiently due to their round surface area and spacing in the pack.

10. What factors determine which cell type to use?

Key considerations include energy density, cost, thermal behavior, mechanical requirements, available space, and target application.

References:

[1] Nagaura, T., & Tozawa, K. (1990). Lithium ion rechargeable battery. Journal of Power Sources, 26(1–2), 3–10.

[2] Bandhauer, T. M., Garimella, S., & Fuller, T. F. (2011). A critical review of thermal issues in lithium-ion batteries. Journal of The Electrochemical Society, 158(3), R1–R25.

[3] International Energy Agency (IEA). (2023). Global EV Outlook 2023: Battery Technology and Market Trends.

[4] Battery University. (n.d.). Types of Lithium-Ion Cells. Retrieved from: https://batteryuniversity.com

[5] Wikipedia. (2024). Lithium-ion battery. Retrieved from: https://en.wikipedia.org/wiki/Lithium-ion_battery

[6] Thackeray, M. M., Wolverton, C., & Isaacs, E. D. (2012). Electrical energy storage for transportation—approaching the limits of, and going beyond, lithium-ion batteries. Energy & Environmental Science, 5, 7854–7863.

Related News

-

Dec. 2025Lithium-Ion Battery Price Forecast for 2025Learn More

Dec. 2025Lithium-Ion Battery Price Forecast for 2025Learn More -

Aug. 2025How Can Small Lithium Polymer Battery Packs Power IoT Innovation?Learn More

Aug. 2025How Can Small Lithium Polymer Battery Packs Power IoT Innovation?Learn More -

Aug. 2025Why Are Lithium Polymer Batteries the Go-To Choice for Portable Devices?Learn More

Aug. 2025Why Are Lithium Polymer Batteries the Go-To Choice for Portable Devices?Learn More -

Jun. 2025Revolutionizing Drone Logistics in Cold Climates with Next-Gen BatteriesLearn More

Jun. 2025Revolutionizing Drone Logistics in Cold Climates with Next-Gen BatteriesLearn More -

Jun. 2025The Future of Smart Glass Batteries: Trends and Innovations for 2025Learn More

Jun. 2025The Future of Smart Glass Batteries: Trends and Innovations for 2025Learn More -

Apr. 2025Top 6 Reasons Why LiFePO4 Lithium Batteries Are Revolutionizing Energy StorageLearn More

Apr. 2025Top 6 Reasons Why LiFePO4 Lithium Batteries Are Revolutionizing Energy StorageLearn More -

Apr. 2025The Ultimate Guide to Li Polymer Battery Packs: Choosing the Right Power SolutionLearn More

Apr. 2025The Ultimate Guide to Li Polymer Battery Packs: Choosing the Right Power SolutionLearn More -

Apr. 2025Why Cylindrical LiFePO4 Cells Are Revolutionizing Energy Storage SolutionsLearn More

Apr. 2025Why Cylindrical LiFePO4 Cells Are Revolutionizing Energy Storage SolutionsLearn More -

Mar. 2025Understanding LiFePO4 Prismatic Cells: A Comprehensive GuideLearn More

Mar. 2025Understanding LiFePO4 Prismatic Cells: A Comprehensive GuideLearn More -

Mar. 2025Lithium Iron Phosphate (LiFePO4) vs Lithium-Ion Battery: A Comprehensive ComparisonLearn More

Mar. 2025Lithium Iron Phosphate (LiFePO4) vs Lithium-Ion Battery: A Comprehensive ComparisonLearn More -

Jan. 2025All You Need To Know About Smart Watch BatteriesLearn More

Jan. 2025All You Need To Know About Smart Watch BatteriesLearn More -

Dec. 2024The Ultimate Guide to Choose the Best Rechargeable Battery for Bluetooth SpeakersLearn More

Dec. 2024The Ultimate Guide to Choose the Best Rechargeable Battery for Bluetooth SpeakersLearn More -

Nov. 2024How Drone Manufacturers Choose Lithium BatteriesLearn More

Nov. 2024How Drone Manufacturers Choose Lithium BatteriesLearn More -

Nov. 2024How medical device vendors choose lithium medical batteriesLearn More

Nov. 2024How medical device vendors choose lithium medical batteriesLearn More -

Sep. 2024Why global enterprises should choose Chinese lithium battery manufacturersLearn More

Sep. 2024Why global enterprises should choose Chinese lithium battery manufacturersLearn More -

May. 2024How to choose lithium battery customized manufacturersLearn More

May. 2024How to choose lithium battery customized manufacturersLearn More -

Mar. 2024How to wake up a dormant lithium battery and bring it back to performanceLearn More

Mar. 2024How to wake up a dormant lithium battery and bring it back to performanceLearn More -

Mar. 2024What should be considered when charging lithium batteriesLearn More

Mar. 2024What should be considered when charging lithium batteriesLearn More