The Ultimate Guide to Li Polymer Battery Packs: Choosing the Right Power Solution

In an era where portable power defines technological progress, Li polymer battery packs have become the cornerstone of modern energy storage. As a leading rechargeable li ion battery supplier, Honcell brings you an in-depth exploration of this game-changing technology, revealing why 72% of OEMs now prefer these flexible power solutions over conventional alternatives.

What Makes Li Polymer Battery Packs Unique?

Li polymer batteries (LiPo) revolutionized energy storage through:

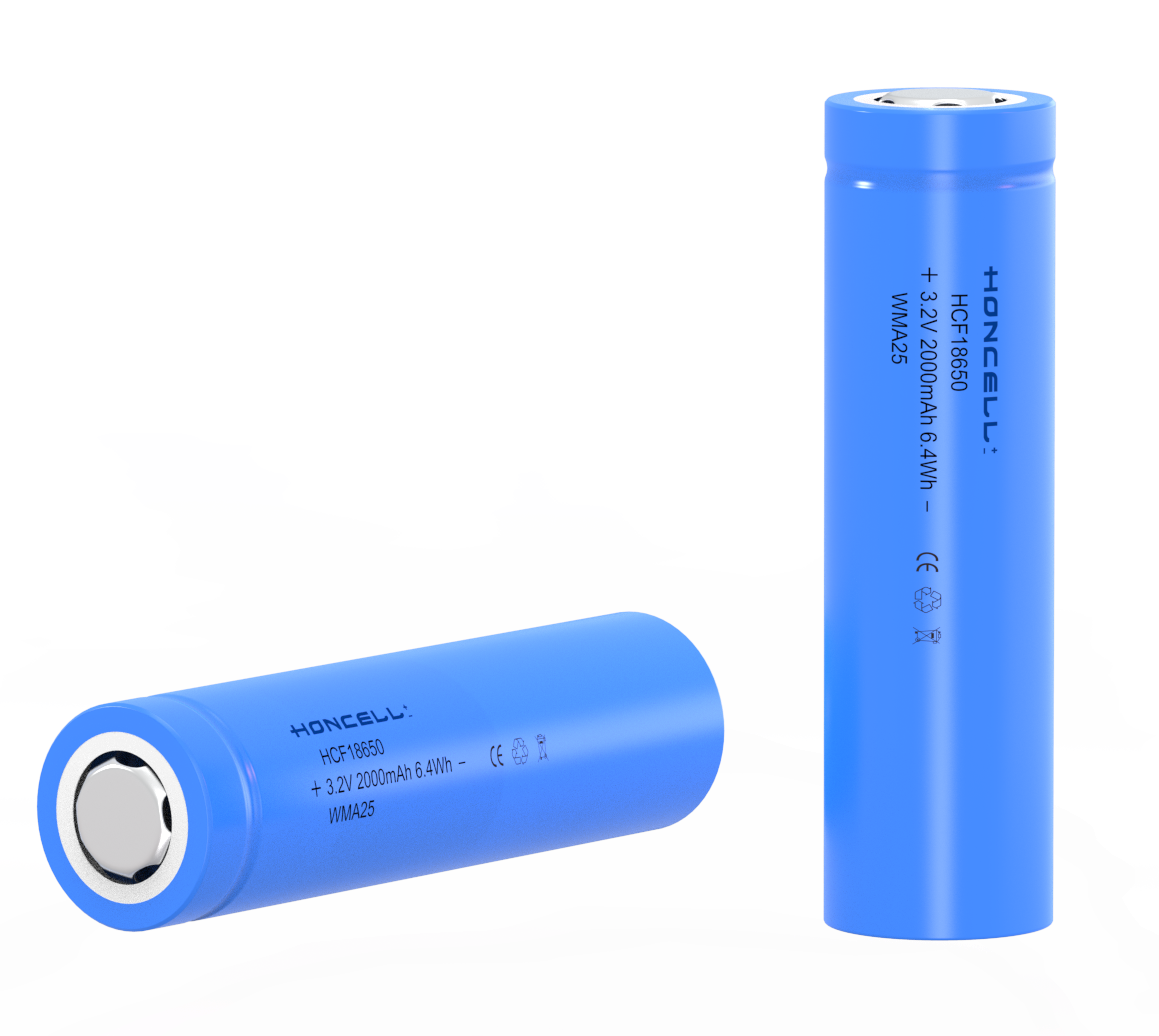

Adaptable Form Factors: Ultra-thin designs (as slim as 0.4mm) enable integration into curved/wearable devices

Energy Density Advantage: 15-20% higher capacity compared to cylindrical li ion cell types

Enhanced Safety: Stable solid/gel polymer electrolytes minimize leakage risks

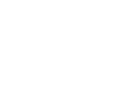

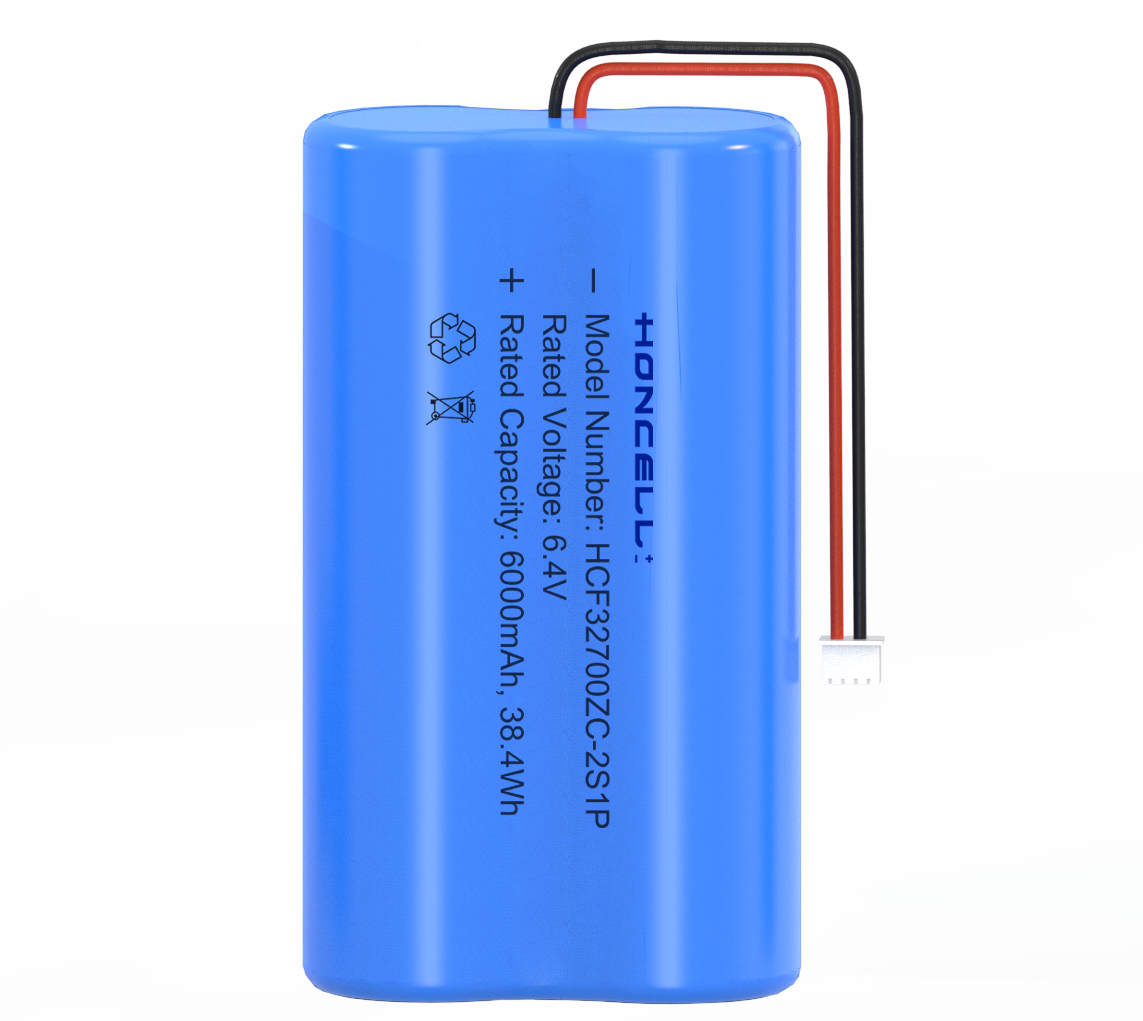

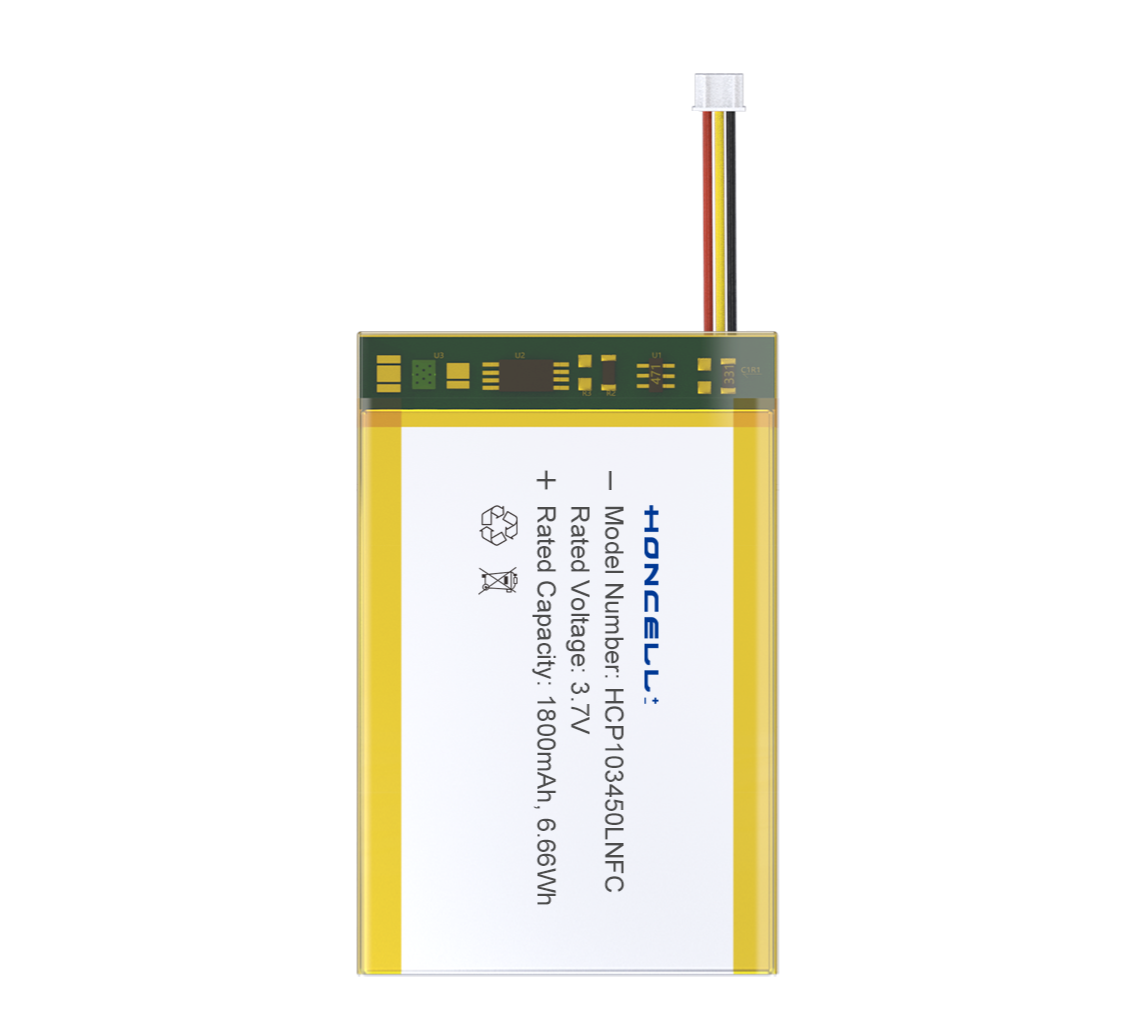

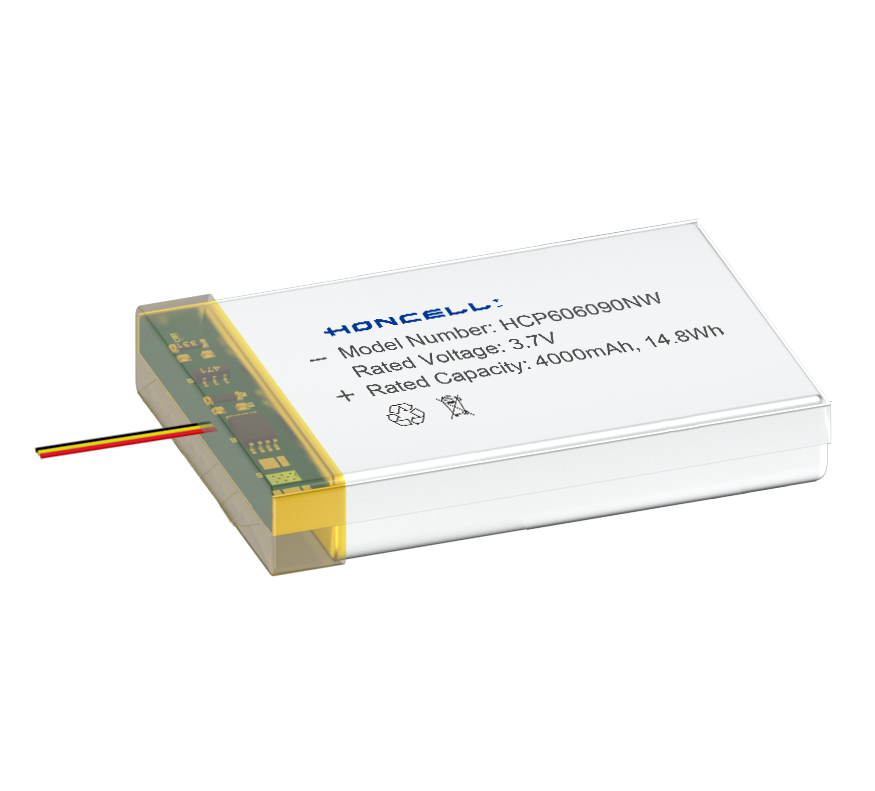

Our HCG Li Polymer Battery Pack series exemplifies these traits, offering customizable shapes without compromising on 4.35V high-voltage performance.

Critical Applications Driving Market Growth

A. High-Performance Scenarios

Medical devices requiring 10C+ discharge rates

Drone batteries demanding >100A continuous output

Instant-start automotive systems

B. Space-Constrained Innovations

IoT sensors needing coin-cell profiles

Foldable electronics requiring bendable power sources

Case Study: A smartwatch manufacturer increased runtime by 40% after switching to our 603048 LiPo packs (3.7V 280mAh).Understanding Critical Performance Factors for Li Polymer Battery Packs

Selecting the right Li polymer battery pack requires a deep understanding of performance characteristics, especially when your application demands high discharge LiPo cells. Here’s how to evaluate key technical aspects without relying on complex data tables:

1. Cycle Life: Aligning Durability with Use Cases

The lifespan of a LiPo battery depends heavily on how it’s used:

Basic Applications: Suitable for low-power devices where occasional cycling is sufficient.

Moderate Demands: Ideal for equipment requiring regular but controlled energy output.

High-Intensity Scenarios: Designed for high discharge LiPo cells in applications like drones or industrial tools, where frequent deep cycling is unavoidable.

Always prioritize suppliers who clarify testing conditions, as real-world performance can differ significantly from lab benchmarks.

2. Discharge Capability: Power When You Need It Most

Discharge rates determine how effectively a battery meets sudden power demands:

Standard Output: Adequate for everyday electronics with steady energy needs.

Elevated Performance: Necessary for tools or systems requiring bursts of energy.

Extreme Power Delivery: Critical for high discharge LiPo cells used in racing drones, emergency systems, or high-performance robotics.

Mismatched discharge rates can lead to inefficiencies or device failures, so align specifications with your project’s peak power requirements.

3. Operating Conditions: Thriving in Challenging Environments

LiPo batteries must perform reliably across temperature extremes:

Controlled Settings: Suitable for indoor or mild-climate applications.

Rugged Environments: Built to withstand harsh outdoor or industrial conditions.

Specialized Use: Engineered for extreme temperatures, such as aerospace or Arctic operations.

For high discharge LiPo cells, thermal management is non-negotiable. Seek packs with advanced heat dispersion features, like layered separators or reinforced terminals.

4. Safety and Reliability: Protecting Your Investment

High discharge applications amplify risks, making these safeguards essential:

Intelligent Protection Circuits: Prevent overloading, short circuits, and voltage drops.

Innovative Materials: Emerging technologies, like self-healing electrolytes, enhance long-term durability.

Certifications: Ensure compliance with international safety standards for peace of mind.

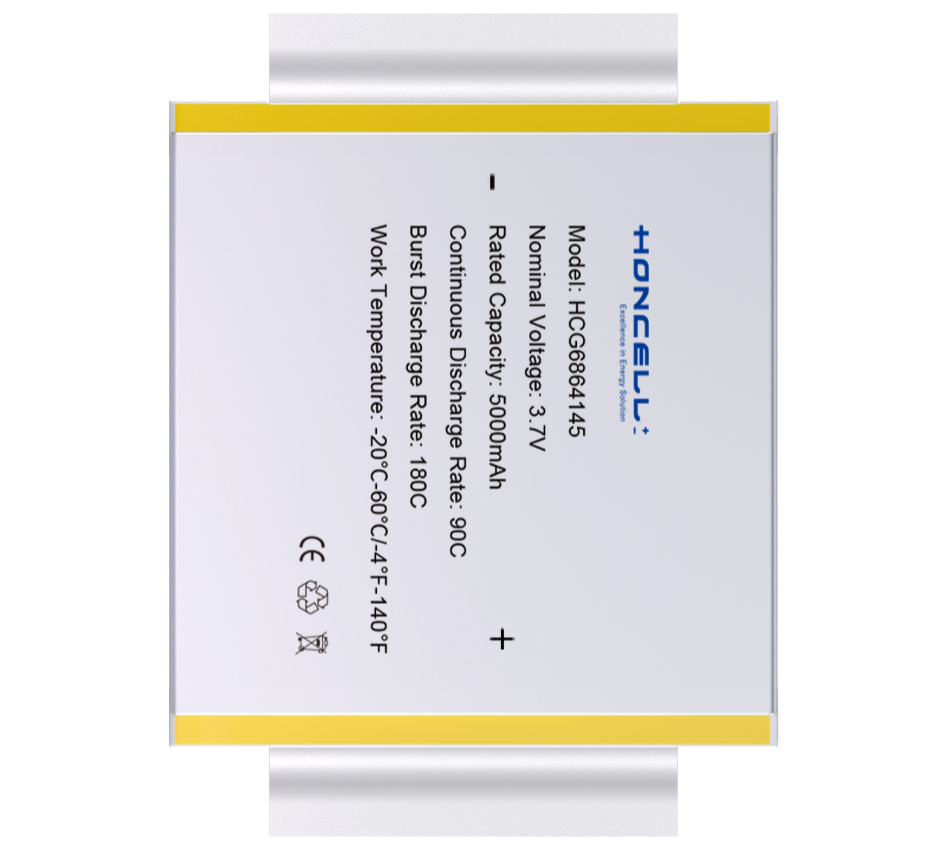

LiPo vs Other Lithium Technologies

Li Polymer vs Li-Ion:

Weight: LiPo offers 10-15% weight reduction

Form Freedom: No rigid metal casing constraints

Cost: 8-12% higher than 18650 cells but enables compact device architecture

LiPo vs LifePO4:

Energy density: 160-200Wh/kg (LiPo) vs 90-120Wh/kg (LiFePO4)

Cycle life: 1,200 vs 2,000 cycles

6-Step Selection Formula for Buyers

Capacity Needs: Match mAh to runtime requirements (not peak draw)

Discharge Profile: Continuous vs pulse current demands

Environmental Factors: IP ratings for moisture/dust exposure

Certifications: UL2054, IEC62133, UN38.3 compliance

Supplier Capabilities:

In-house R&D for custom lithium battery solutions

100% cycle/testing facilities

Minimum 50,000pcs/month production capacity

6. Thermal Management: Verify heat dissipation designs for high discharge Lipo cells

Honcell’s engineering team uses proprietary 3D modeling to optimize these parameters across 20+ HCG series configurations.

Emerging Innovations

Solid-State LiPo: 400Wh/kg prototypes under testing

Fast-Charge Tech: 0-80% in 12 minutes without dendrite formation

Self-Healing Polymers: Microcapsule-based electrolyte repair

Powering the Future Responsibly

As devices evolve from rigid to organic forms, Li polymer battery packs stand poised to enable the next generation of portable tech. Whether you require standard 3.7V packs or high discharge Lipo cells for extreme applications, partner with suppliers offering:

ISO-certified lithium battery solutions

10+ years of scalable manufacturing expertise

Prototyping-to-mass-production continuity

Explore Honcell's Li Polymer Battery Packs or consult our engineers for application-specific power designs.

Related News

-

Dec. 2025Lithium-Ion Battery Price Forecast for 2025Learn More

Dec. 2025Lithium-Ion Battery Price Forecast for 2025Learn More -

Aug. 2025How Can Small Lithium Polymer Battery Packs Power IoT Innovation?Learn More

Aug. 2025How Can Small Lithium Polymer Battery Packs Power IoT Innovation?Learn More -

Aug. 2025Why Are Lithium Polymer Batteries the Go-To Choice for Portable Devices?Learn More

Aug. 2025Why Are Lithium Polymer Batteries the Go-To Choice for Portable Devices?Learn More -

Jun. 2025Revolutionizing Drone Logistics in Cold Climates with Next-Gen BatteriesLearn More

Jun. 2025Revolutionizing Drone Logistics in Cold Climates with Next-Gen BatteriesLearn More -

Jun. 2025The Future of Smart Glass Batteries: Trends and Innovations for 2025Learn More

Jun. 2025The Future of Smart Glass Batteries: Trends and Innovations for 2025Learn More -

Apr. 2025Top 6 Reasons Why LiFePO4 Lithium Batteries Are Revolutionizing Energy StorageLearn More

Apr. 2025Top 6 Reasons Why LiFePO4 Lithium Batteries Are Revolutionizing Energy StorageLearn More -

Apr. 2025The Ultimate Guide to Li Polymer Battery Packs: Choosing the Right Power SolutionLearn More

Apr. 2025The Ultimate Guide to Li Polymer Battery Packs: Choosing the Right Power SolutionLearn More -

Apr. 2025Why Cylindrical LiFePO4 Cells Are Revolutionizing Energy Storage SolutionsLearn More

Apr. 2025Why Cylindrical LiFePO4 Cells Are Revolutionizing Energy Storage SolutionsLearn More -

Mar. 2025Understanding LiFePO4 Prismatic Cells: A Comprehensive GuideLearn More

Mar. 2025Understanding LiFePO4 Prismatic Cells: A Comprehensive GuideLearn More -

Mar. 2025Lithium Iron Phosphate (LiFePO4) vs Lithium-Ion Battery: A Comprehensive ComparisonLearn More

Mar. 2025Lithium Iron Phosphate (LiFePO4) vs Lithium-Ion Battery: A Comprehensive ComparisonLearn More -

Jan. 2025All You Need To Know About Smart Watch BatteriesLearn More

Jan. 2025All You Need To Know About Smart Watch BatteriesLearn More -

Dec. 2024The Ultimate Guide to Choose the Best Rechargeable Battery for Bluetooth SpeakersLearn More

Dec. 2024The Ultimate Guide to Choose the Best Rechargeable Battery for Bluetooth SpeakersLearn More -

Nov. 2024How Drone Manufacturers Choose Lithium BatteriesLearn More

Nov. 2024How Drone Manufacturers Choose Lithium BatteriesLearn More -

Nov. 2024How medical device vendors choose lithium medical batteriesLearn More

Nov. 2024How medical device vendors choose lithium medical batteriesLearn More -

Sep. 2024Why global enterprises should choose Chinese lithium battery manufacturersLearn More

Sep. 2024Why global enterprises should choose Chinese lithium battery manufacturersLearn More -

May. 2024How to choose lithium battery customized manufacturersLearn More

May. 2024How to choose lithium battery customized manufacturersLearn More -

Mar. 2024How to wake up a dormant lithium battery and bring it back to performanceLearn More

Mar. 2024How to wake up a dormant lithium battery and bring it back to performanceLearn More -

Mar. 2024What should be considered when charging lithium batteriesLearn More

Mar. 2024What should be considered when charging lithium batteriesLearn More